Dubai has quickly become a global center for technology-driven production, manufacturing, and industrial innovation. As factories get bigger and more complicated, making sure that workers are safe has become a top priority. While traditional safety rules are still important, they aren’t enough to deal with the changing dangers that modern factories pose.

- 1. Detecting Hazards in Real Time

- 2. Predictive maintenance for safer operations

- 3. Automated Response to Emergencies

- 4. Better Watching and Monitoring

- Advantages of AI-Powered Surveillance

- 5. Safety improvements based on data

- How Data Analytics Improves Safety

- Benefits

- 6. Keeping an eye on workers’ health

- 7. Working with Smart Factory Solutions

- The main benefits of AI manufacturing security systems

- Questions and Answers about AI Manufacturing Security Systems in Dubai

- Final thoughts

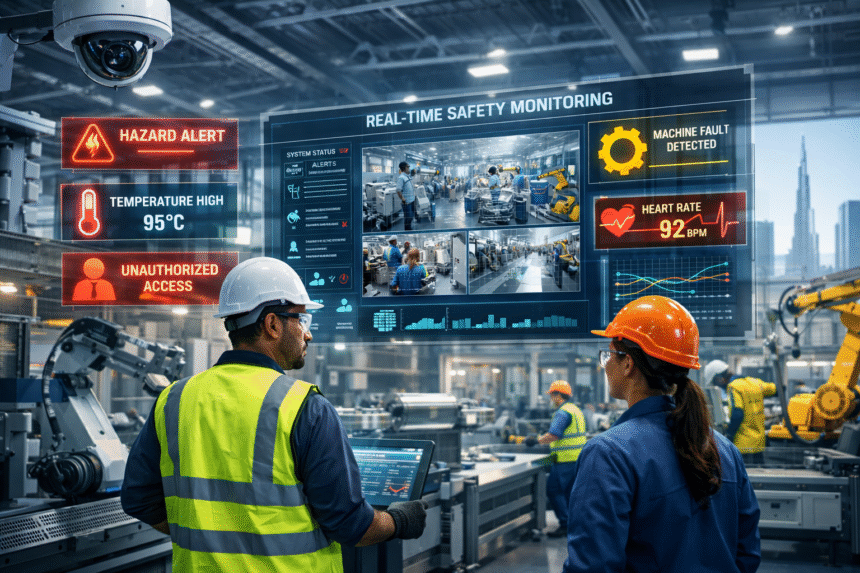

This is where AI Manufacturing Security Systems are changing the game in the industrial sector. These systems use AI, real-time monitoring, predictive analytics, and automation to cut down on accidents, make work more efficient, and keep workers safe. This article talks about seven ways that AI Manufacturing Security Systems make factories safer in Dubai. It is a complete guide for factory owners, managers, and safety officers.

1. Detecting Hazards in Real Time

One of the best things about AI Manufacturing Security Systems is that they can find dangers in real time. AI systems keep an eye on the factory environment all the time, finding possible dangers as they happen. This is different from traditional safety setups that rely on people to watch or static sensors.

How Real-Time Detection Works

AI systems use:

- Cameras with high resolution

- Sensors for motion and heat

- Gas and chemical detectors

- Algorithms for machine learning that can find patterns

These systems can find dangers like:

- Fires or smoke coming out

- Leaks of gas or chemicals

- Equipment getting too hot or not working

- Unsafe actions by workers

- Advantages of Dubai Factories

Dubai’s industrial environment often has high temperatures, heavy machinery, and chemical processing going on. Real-time hazard detection sends out alerts right away, so that people can respond quickly to possible problems. This proactive approach helps keep people from getting hurt, property from being damaged, and production from stopping for a long time, which costs a lot of money.

2. Predictive maintenance for safer operations

A lot of factory accidents happen because machines break down. AI Manufacturing Security Systems use predictive maintenance to find problems with equipment before they get worse and become dangerous.

How Predictive Maintenance Works

Predictive maintenance uses AI algorithms to constantly watch over machines and look for:

- Patterns of vibration

- Changes in temperature

- Changes in pressure

- Cycles of operation

When something goes wrong, maintenance teams get alerts to fix the problem before it causes a failure.

Example

A conveyor belt that shakes in an unusual way could mean that it is about to break down. AI can predict this, so technicians can step in before an accident happens.

- Good things

- Stops accidents that happen with equipment

- Lessens unplanned downtime

- Increases the life of machines

- Cuts down on the cost of emergency repairs

Dubai factories, especially those with high-volume production lines, benefit from this proactive approach, which keeps everyone safe and makes things run more smoothly.

3. Automated Response to Emergencies

When a fire breaks out, a chemical spill occurs, or an electrical fault happens, immediate action is crucial to minimize damage. AI Manufacturing Security Systems can automatically respond to such emergencies, eliminating the need for human intervention in critical moments. These systems can trigger alarms instantly, shut down malfunctioning equipment, activate fire suppression or containment systems, and notify emergency personnel without delay. By automating these responses, AI significantly speeds up reaction times, reducing the likelihood of accidents escalating. The advantages are clear: injuries and fatalities are minimized, property damage is lessened, emergency responses are coordinated efficiently, and factories in Dubai can ensure compliance with safety regulations.

4. Better Watching and Monitoring

Traditional CCTV systems rely on human monitoring to detect unsafe behavior, which can often result in missed events or delayed responses. AI-powered surveillance, on the other hand, uses smart video analytics to continuously monitor the factory floor, ensuring that safety protocols are strictly followed at all times.

How AI Surveillance Works

AI surveillance systems analyze video feeds and sensor data to identify potential safety risks. Key functionalities include:

-

Detecting unsafe behavior: For example, identifying workers who are not wearing required safety gear.

-

Monitoring restricted areas: Detecting unauthorized personnel entering areas they should not access.

-

Analyzing machine usage: Observing how equipment is being operated to identify unsafe patterns or practices.

Advantages of AI-Powered Surveillance

-

Identifies hazards that human monitors might miss: Continuous monitoring reduces the risk of overlooked safety violations.

-

Encourages compliance with safety protocols: Workers are more likely to follow rules when systems consistently enforce them.

-

Enables rapid intervention: Alerts allow supervisors to act immediately to prevent accidents.

-

Promotes a culture of safety: Consistent monitoring and feedback create a safer work environment.

In large-scale manufacturing facilities in Dubai, where hundreds of employees operate complex machinery, smart surveillance is essential for protecting workers and ensuring smooth business operations.

5. Safety improvements based on data

AI systems collect and analyze vast amounts of data from cameras, sensors, and machinery. This data-driven approach allows factories to continuously enhance their safety protocols, ensuring that potential hazards are identified and addressed before they result in accidents.

How Data Analytics Improves Safety

AI-powered analytics provide actionable insights for industrial safety by:

Identifying recurring hazards and accident patterns: AI can detect trends over time, highlighting areas where incidents or near-misses frequently occur.

Recommending workflow and equipment adjustments: By analyzing operational data, AI suggests modifications to machinery settings, workflow sequences, or safety measures to reduce risks.

Supporting employee retraining: AI helps pinpoint unsafe behaviors or common mistakes, guiding targeted training programs for staff to improve safety practices.

Enabling strategic safety investments: Insights from AI analytics allow management to prioritize investments in equipment, technology, or safety systems that will have the most significant impact.

Benefits

Continuous improvement of safety standards: AI helps factories evolve their protocols in response to real-world data.

Reduction of workplace accidents over time: Predictive insights allow preemptive action, decreasing the likelihood of injuries.

Data-driven decision-making: Managers can make informed choices based on objective safety data rather than intuition.

Proactive safety culture: AI encourages a mindset where potential risks are addressed before they escalate.

By leveraging AI analytics, factories in Dubai can make informed, strategic decisions to create safer, more efficient workplaces. This approach ensures that safety measures are not static but constantly adapting to changing conditions and emerging hazards.

6. Keeping an eye on workers’ health

AI Manufacturing Security Systems can do more than just watch machines; they can also watch workers’ health. Wearable devices keep track of important signs like:

- Heart rate

- The temperature of the body

- How tired you are

Keeping an eye on workers’ health can help stop accidents caused by tiredness, heat stress, or exhaustion.

Advantages

- Stops things from happening because of tiredness

- Helps employees stay healthy overall

- Increases output

- Combines health alerts with safety rules for factories

This feature keeps workers safe and productive in Dubai, where many industrial workers work long hours in tough conditions.

7. Working with Smart Factory Solutions

IoT devices, automated logistics, and energy management systems are making modern manufacturing more and more connected. These smart factory solutions work perfectly with AI Manufacturing Security Systems, making a complete safety ecosystem.

- Benefits of Integration

- Alerts and monitoring from one place

- Working together with many factory systems

- Better operational efficiency

- Better hazard prevention through insights across the system

This integration makes sure that every part of the factory runs safely and at its most efficient level.

The main benefits of AI manufacturing security systems

There are many benefits for factories in Dubai when they invest in AI Manufacturing Security Systems:

Fewer accidents at work: Predictive maintenance and real-time monitoring stop accidents from happening.

Regulatory Compliance: AI makes sure that safety rules are followed in both the US and other countries.

Operational Efficiency: Automated monitoring and emergency responses make things run more smoothly.

Insights Based on Data: Using analytics to make things better all the time lowers risks over time.

Health monitoring keeps workers safe, awake, and productive.

These benefits make AI systems essential for factories that want to be safe, efficient, and grow over time.

Questions and Answers about AI Manufacturing Security Systems in Dubai

1. What are AI Manufacturing Security Systems?

AI-powered advanced systems that keep an eye on factories, find dangers, and make the workplace safer.

2. What do these systems do to make factories safer?

By keeping an eye on health, finding hazards in real time, doing predictive maintenance, and automating emergency responses.

3. Do these systems work well in Dubai factories?

Yes, especially for big, high-tech factories.

4. Is it possible for AI to keep an eye on the health of workers?

Yes, wearable devices keep an eye on your heart rate, temperature, and fatigue to keep you safe.

5. Do AI systems work with other technologies in the factory?

Of course. They connect with smart factory solutions to improve safety and operational efficiency across the board.

6. How fast do AI systems react in an emergency?

AI reacts right away, setting off alarms and safety measures right away.

7. Are AI security systems for manufacturing worth the money?

Yes. The long-term benefits of preventing accidents, reducing downtime, and following the rules are greater than the initial costs.

Final thoughts

AI Manufacturing Security Systems make factories in Dubai safer by using smart factory solutions to combine real-time monitoring, predictive maintenance, automated emergency response, intelligent surveillance, data-driven improvements, and worker health monitoring.

For business leaders in Dubai, using AI-based safety systems is more than just a safety measure; it’s a smart investment. Factories that use these systems keep their workers safe, lower the risks of running the business, make sure they follow safety rules, and boost productivity. Smart, proactive, and AI-powered technology will make Dubai’s industrial safety better in the future.